A Guide on Top-Quality Milling Machines

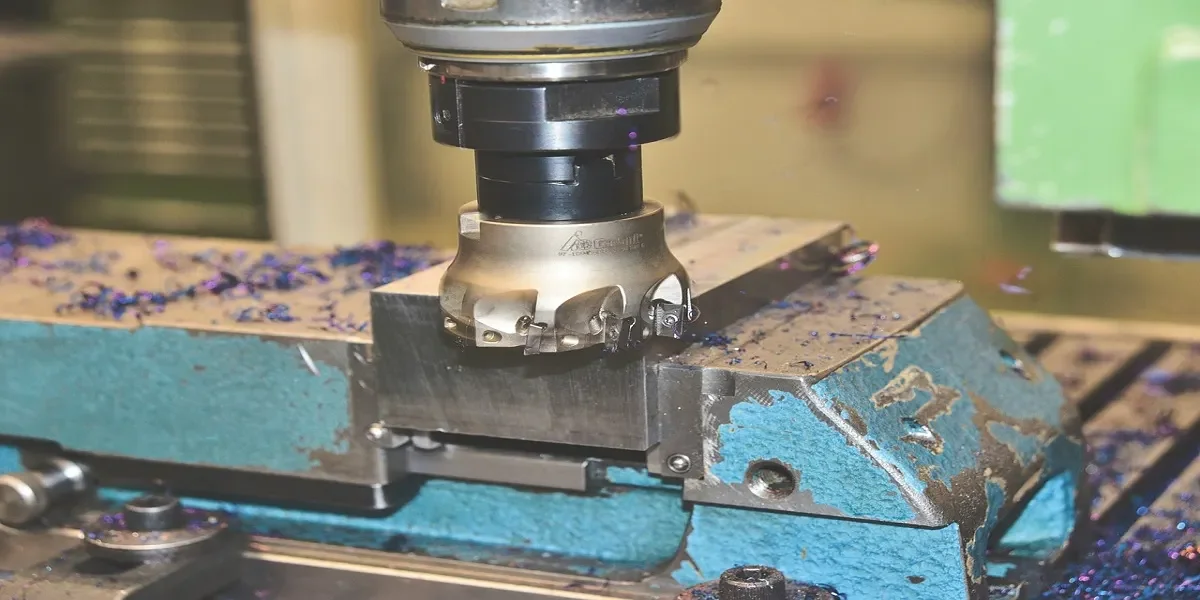

Milling machines are essential tools in the manufacturing and engineering industries. These machines use rotary cutters to remove material from a workpiece and are used to produce precise shapes and surfaces. Milling can be done manually or with the help of computer numerical control (CNC), which automates the process for increased accuracy and speed.

Milling machines vary in complexity, size, function, and precision. From hobby workshops to large-scale industrial settings, they play a key role in the creation of mechanical parts, prototypes, molds, and finished goods across numerous industries, including automotive, aerospace, electronics, and construction.

Why Milling Machines Are Important in Today’s Industries

The demand for precision and efficiency in product manufacturing has never been higher. Milling machines meet this demand in multiple ways:

-

Precision Engineering: Enables the manufacturing of intricate and accurate parts.

-

Productivity: CNC milling machines can run non-stop and handle complex tasks with minimal human intervention.

-

Versatility: Useful for drilling, cutting, boring, and producing customized parts.

-

Customization: Important for prototyping and bespoke components in industries like medical devices or aviation.

Key Sectors That Rely on Milling Machines

| Industry | Application of Milling Machines |

|---|---|

| Automotive | Engine components, transmission parts |

| Aerospace | Structural parts, turbine blades |

| Electronics | PCB milling, casings |

| Construction | Custom tool parts, panel cutting |

| Medical | Surgical instruments, implants |

Recent Trends and Innovations in Milling Machines (2024–2025)

Recent developments in the field reflect advancements in digital technology and automation:

-

Smart CNC Integration (2024): CNC machines are becoming smarter with AI integration. Features like real-time error detection, energy efficiency analytics, and predictive maintenance have improved productivity.

-

Hybrid Machines (2025): Many manufacturers now combine milling with other techniques like 3D printing or laser cutting in one machine, offering greater flexibility.

-

Eco-Friendly Designs: There's an increasing trend toward energy-efficient motors and coolant systems to reduce the environmental footprint.

-

Compact Models for SMEs: Portable and space-saving designs are becoming popular among small-scale industries and educational institutions.

These trends show a growing trust in automation and an emphasis on reducing waste, energy use, and human error in the machining process.

Regulations and Standards Governing Milling Machines

While there are no specific international bans or limitations on milling machines, they are subject to several national and global standards to ensure safety and precision. Below are key regulatory considerations:

-

ISO Standards:

-

ISO 10791: Specifies testing procedures for machining centers, including milling machines.

-

ISO 23125: Deals with safety requirements for metal-cutting machines.

-

-

OSHA Guidelines (U.S.):

-

Mandates proper guarding, emergency stops, and safety training for operators.

-

-

CE Certification (Europe):

-

Machines sold in Europe must meet the European Machinery Directive (2006/42/EC).

-

India-Specific Regulation Example:

In India, the Factories Act, 1948 mandates safety protocols for operating heavy machinery, including periodic inspections and operator training.

Government-supported skill development programs such as Skill India and MSME Development Institutes also offer subsidized training on the operation and maintenance of such machinery.

Helpful Tools and Resources

For individuals and businesses looking to explore, learn about, or invest in milling machines, several resources are available:

-

CAD/CAM Software: Tools like SolidWorks, AutoCAD, and Fusion 360 help in designing parts before milling.

-

Simulation Tools: CNC Simulator Pro or NC Viewer can simulate operations to prevent errors.

-

Machine Selection Portals:

-

IndiaMART, Alibaba, and ThomasNet allow you to compare models and suppliers.

-

-

Learning Platforms:

-

Coursera, edX, and Udemy offer courses on CNC machining and milling basics.

-

-

Calculators:

-

Online cutting speed and feed rate calculators are useful for professionals.

-

-

Maintenance Apps:

-

Apps like MachineMetrics or UpKeep help in preventive maintenance and tracking machine health.

-

These tools ensure smoother project execution, reduced waste, and improved learning for both professionals and beginners.

Frequently Asked Questions (FAQs)

1. What are the different types of milling machines?

There are several types:

-

Vertical Milling Machines: The spindle axis is vertical; ideal for simple and precise cuts.

-

Horizontal Milling Machines: Spindle runs horizontally; suited for heavy-duty tasks.

-

Universal Milling Machines: Can perform both vertical and horizontal functions.

-

CNC Milling Machines: Operated via computer programs for precision automation.

2. What materials can be milled?

Milling machines can process a wide range of materials, including:

-

Metals (aluminum, steel, brass)

-

Plastics (acrylic, PVC)

-

Wood

-

Composite materials

3. How does CNC milling differ from manual milling?

CNC milling uses computer-controlled instructions to automate tool movements. It offers:

-

Greater precision

-

Higher repeatability

-

Less manual labor

-

Safer operation

Manual milling, on the other hand, requires constant human control.

4. Are there any safety precautions when using milling machines?

Yes. Essential precautions include:

-

Wearing proper protective gear (gloves, goggles)

-

Ensuring emergency stop buttons are functional

-

Regular machine maintenance

-

Proper machine guarding and ventilation

5. How can small businesses afford high-quality milling machines?

Options include:

-

Purchasing refurbished equipment

-

Leasing instead of buying

-

Applying for government subsidies or grants

-

Utilizing shared spaces such as fabrication labs or maker spaces

Conclusion

Top-quality milling machines are a cornerstone of modern manufacturing. As industries grow increasingly reliant on precision and automation, these machines provide unmatched value in production, customization, and design. Staying informed about trends, safety regulations, and available tools helps both businesses and individuals leverage these machines effectively.

Whether you're a student, small business owner, or industry expert, understanding milling machines—what they do, how they work, and how they’re evolving—is key to staying competitive and innovative in today’s manufacturing world.